Tiva 900 - 1000 - Washer Disinfectors for Hospitals

Tiva 1000 and Tiva 900 presents the highest and the newest standards of flexible full system Washers for washing, disinfection, drying and validation of medical and laboratory items. Loading and unloading operations can be performed by manual or automatic trolleys, connected to a conveyor system. Tiva 1000 model is ideal for surgical and anesthesia items centralized treatment, having 2 washers placed side by side enable the treatment of large items quantities with CSSD.

Optional Features Hot Air Drying

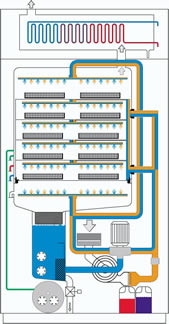

- A drying unit with performances of 500 mc/h, equipped with two filters system:

- Pre-filter F-class

- Hepa Filter H14

- Heating power 6 Kw

- Air drying distribution by double tubes, for a perfect and complete distribution with the chamber, baskets level and injectors Steam condenser. The condensate drains into the chain directly

- Steam, electrical or mixed feed

- Printer located next to the washer for cycle data validation and traceability

- Separate rinsing

- Purified water connection (osmotic)

- External trolley Motorized system for washer loading and unloading procedures

- Automatic loading and unloading baskets system

- Boiler with 18Kw for pre-heating DEMI water

- 4th chemical products dosing pump with flow meters quantity measurements and products check equipped with minimum level warning alarm

|

CONTROL SYSTEM The new electronic control system entitles to optimize the washing process and to personalize thermo disinfection programs to be performed on demand of the principal validated parameters tracking, as stated by the European norms.

|

Washer Trolley

C210 Automatic trolley for loading/unloading baskets. |

C200

C200Semi automatic trolley for loading/unloading baskets equipped with self-locking wheels. |

Design and Construction

|

Body

|

|

Door Features

|

|

Baskets

|

|

Trolley

|

- A thermo disinfection

with 93°C temperature. Programmable for various time and temperature, for each single cycle, in order to satisfy and meet different thermo disinfection regulations - The temperature

is controlled by 2 PT1000 independent temperature sensors

2 Separated PT1000 temperature sensor probes, one for disinfection control and the other for record - The water quantity

usage controlled by a volumetric system to allow the cycle consumption economization

A pressure switch is used to control and monitor the right pump and piping pressure

Chemical Products

Chemical Products

- Equipped with 3 chemical products dosing pumps, controlled completely by the micro-processor and a flow meter with the possibility to modify the required chemical quantity in each cycle.

- Chemical products (liquid only) quantity control, with minimum level alarm.

- 3 built in chemical products containers.